SpaceA

SIMPLE, FAST AND COMPETITIVE

SpaceA technology is based on the layer-by-layer deposition of one molten thermoplastic.

A solid component can be built up by solidifying this melt strand.

Yizumi SpaceA technology is developed with key features to ensure efficiency and high productivity:

- Single screw extruder

- 6-axis robotic positioning system

- Drying unit for material pre-treatment

- Industry standard control system

Material diversity

The screw plasticizing unit is operated with conventional thermoplastic granulate. This enables the processing of unfilled, but also highly filled plastic compounds.

Productivity

The high process productivity is based on the physical principle of shear heating within the screw extruder. SpaceA can deliver high throughput with low manual efforts and low energy consumption.

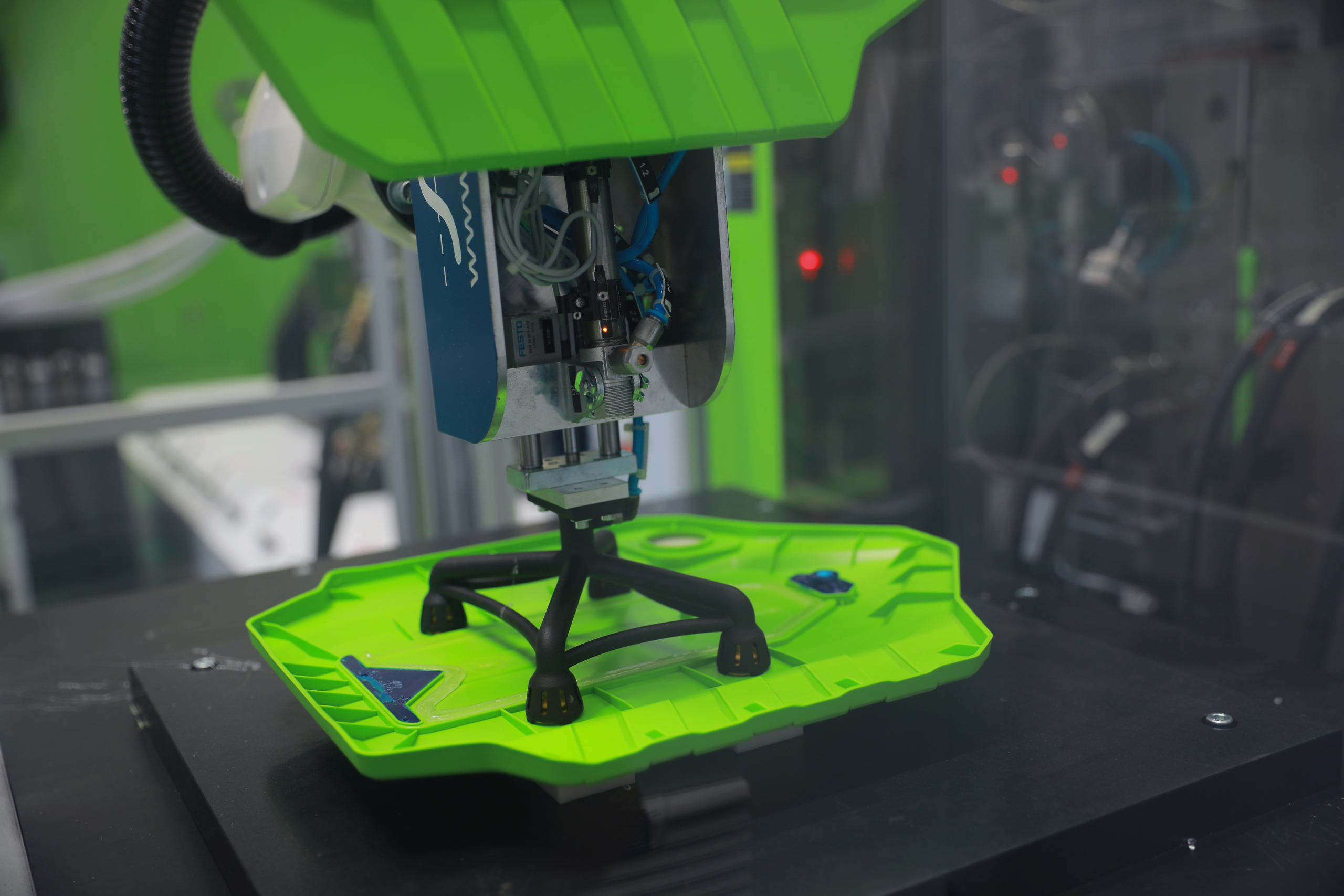

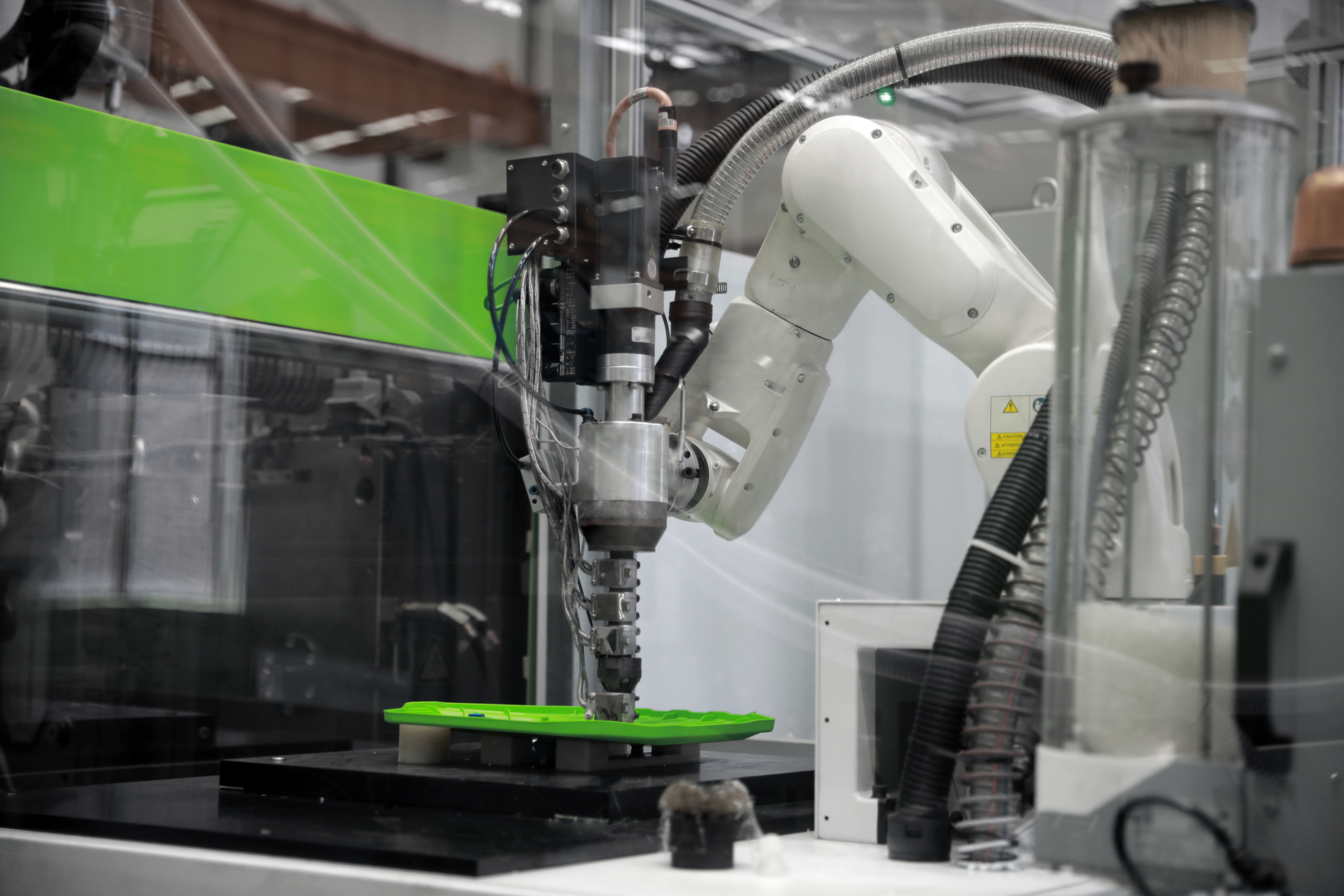

High level of automation

SpaceA is equipped with a 6-axis industrial robot to bypass size and design complexity limitations. Additive structure and machining are combined in one manufacturing system allowing the integration of inserts such as threaded or bearing bushes, injection molded parts or electronic components.

Flexibility and scalability

In the SpaceA, the platform module and the print module are separated to provide high flexibility. The modularity allows easy integration of the system with existing production lines.