HII-S

EFFICIENT, PRECISE E STABLE

HII-S die-casting machines (ranging from 180 to a 5000 tons of clamping force) are designed and developed to ensure high levels of efficiency and consistent casting quality.

The injection unit has been designed to achieve high production consistency. The control system of the HII-S is developed according international standards.

HII-S die-casting machines come equipped with a centralized and automatic lubrication system.

In order to ensure the highest levels of reliability and efficiency, all units of the HII-S die-casting machines (clamping unit, injection system, hydraulic system) are tested separately before assembly, and then retested once they are integrated into the machine.

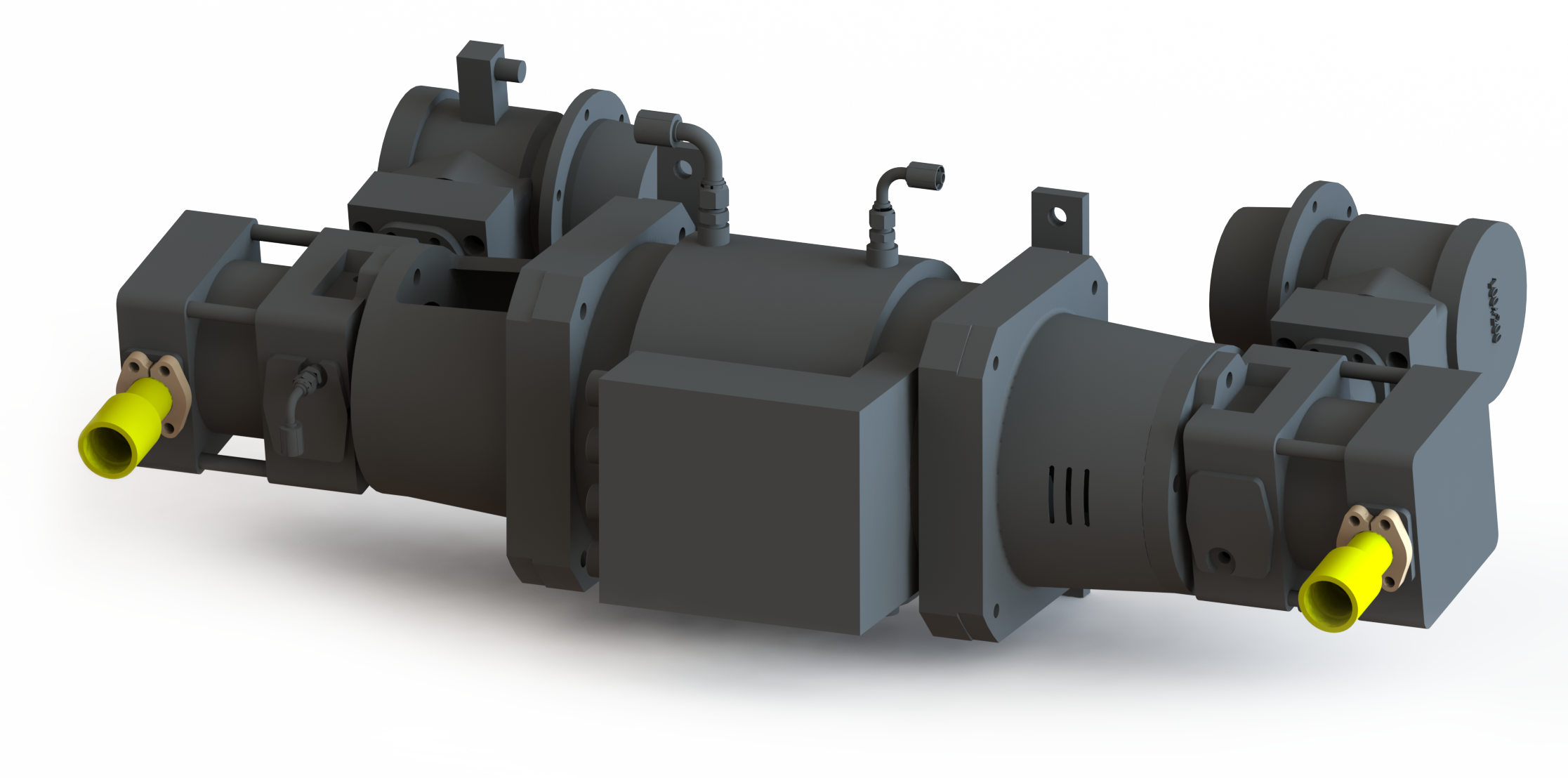

Hydraulic system

The hydraulic system of the HII-S series has been designed to ensure high productivity and process stability. The high efficiency of the hydraulic system allows for cycle times optimization with low energy consumption.

The hydraulic circuit is characterized by an efficient thermal dissipation function and an advanced filtration system. This allows the die-casting machine to operate with consistently clean fluid at a low temperature.

Servo-motor for energy saving

HII-S die-casting machines can be equipped with a brushless motor pump that provides high responsiveness during all hydraulic movements of the machine.

The use of brushless motors ensures significant energy savings while maintaining performance and productivity.

The energy-saving servo motor is available upon request for all HII-S die-casting machines, ranging from 380 to 4500 tons.

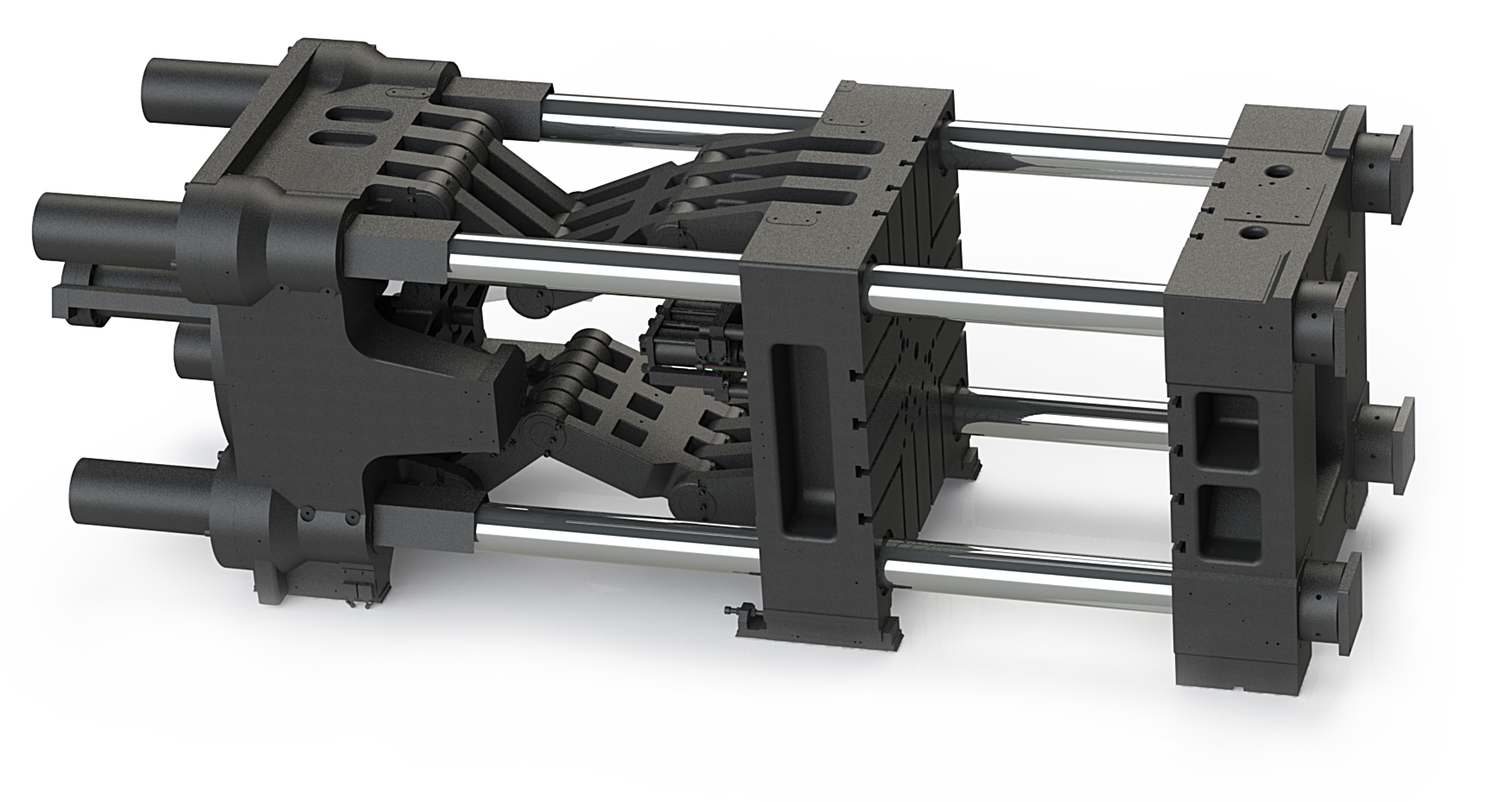

Reliable clamping unit

Faster opening and closing movements

Toggle system with optimized mechanical structure and high rigidity of the plates.

The plates are designed with FEM to ensure better force distribution and, consequently, a longer lifespan.

The closing system of the HII-S allows for reduced cycle times through faster opening and closing movements compared to traditional die-casting machines.

Automatic mould height adjustment with automatic locking is functional in achieving high levels of efficiency.