THIXOMOLDING

PRODUCTION OF “NEAR-NET-SHAPE” PARTS

YIZUMI began developing Thixomolding technology in 2009, becoming the first Chinese manufacturer to market a machine for the injection of semi-solid state magnesium alloy.

Today, the MG II series can meet various production needs with machines ranging from 180 to 3200 tons of clamping force.

The MG II series incorporates several innovations developed and patented by YIZUMI, such as the hot runner technology and the multi-gate injection system used for flat or frame parts production. This system is developed to optimize the cavity filling process, reduce mold material usage by 15% to 30%, and achieve high levels of production standardization.

Redesigned clamping unit

The clamping unit has been redisegned to ensure uniform stress distribution and lower platen deformation

High-speed mold opening and closing technology

Specific patented technologies to ensure smooth and high-speed die opening and closing movements

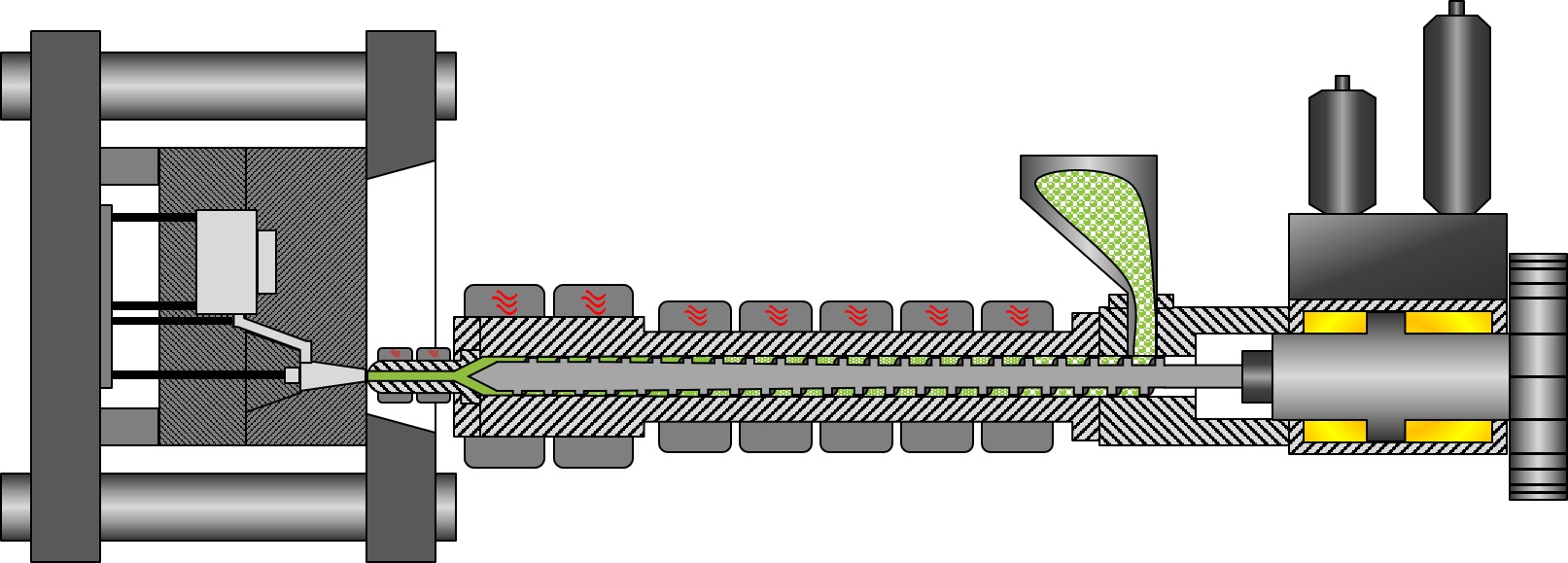

Robust and durable screw/barrel unit

The screw/barrel unit is made with highly durable and reliable materials

Innovative injection system

High-speed closed-loop injection control technology to ensure a reliable, stable and highly repeatable process